Ecosmart

Our flagship controls platform, is an easy and cost-effective control solution – true demand control ventilation at your fingertips. Ecosmart systems can be controlled in many ways, including various sensors and controllers. However, here, we explore how to control Ecosmart using external controllers, such as Building Management Systems (BMS).

Ecosmart Connect and Adapt Trend Systems with BACnet

Some Nuaire products, such as the XBC+ range, can be supplied with a fully integrated Trend IQ422/12/LAN/BAC/230 Excite internal controller as an alternative to basic Ecosmart Classic controls. These Ecosmart Adapt devices can be fully incorporated into a Trend or BACnet system over IP BMS and offer a full range of features. There are numerous Trend and BACnet control devices available on Nuaire products – this piece covers the basic BMS functions native to every Ecosmart Classic fan controller when combined with the ES-CI (control interface).

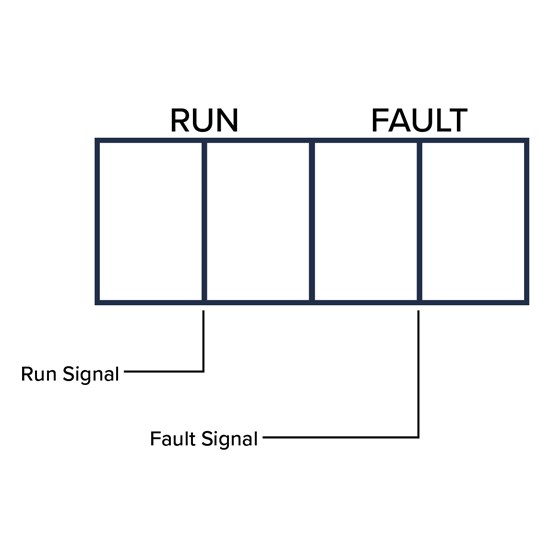

One of the most basic requirements when connecting to a BMS is the ability to monitor the fan status. Ecosmart makes this basic requirement simple to implement by providing Volt Free Relay Contacts to indicate each condition. These contacts operate like switches; the ‘Run’ contacts are closed when the fan is running, and the ‘Fault’ contacts are closed when there is no fault (to indicate the status is ok).

In the event of a fault occurring on the system, the ‘Fault’ contact will go open circuit. These switched contacts can be connected to any BMS or control panel to monitor the fan system. In general, they are rated at 5A resistance, 0.5A inductive, but contractors are advised to check the appropriate I&M manual before switching loads with these connections.

In the event of a fault occurring on the system, the ‘Fault’ contact will go open circuit. These switched contacts can be connected to any BMS or control panel to monitor the fan system. In general, they are rated at 5A resistance, 0.5A inductive, but contractors are advised to check the appropriate I&M manual before switching loads with these connections.

The Ecosmart Control Interface (ES-CI)

The ES-CI connection device can be added to any fan by simply connecting it to the ‘NET’ link socket on-board the Ecosmart device. It provides a whole host of terminals available to a BMS to control the fan. This device can be placed at the fan or brought remotely (up to 300 metres) to the control panel or interface outstation by simply extending the 4-core SELV link wire (available from Nuaire).

Note for installers – do not run the data cable in the same conduit as the mains cables and ensure that there is a 50mm separation between the data cable and other cables.

The Fan Terminal – Enable/Disable

This is a simple volt-free contact which, when closed by a switch or relay, will turn on the fan. The speed at which the fan runs when enabled is governed by the following terminals:

Min/Max – Speed Control (Trickle and Boost)

The most basic form of speed control is trickle and boost. The ES-CI makes this function very simple via a BMS. Once minimum and maximum speed positions have been set on the commissioning dials, these speeds can be selected by connecting the ‘select’ terminal to either min or max. When ‘select’ is connected to ‘min’ the fan will run at its trickle speed (set by the ‘min’ dial) and conversely at its boost speed (set by the ‘max’ dial) when ‘select’ is connected to ‘max’.

The fan needs to be enabled by closing the ‘fan’ contact. In this way, a simple three-position speed controller can be achieved with off, trickle and boost being easily selectable.

0V-10V – Variable Speed Control

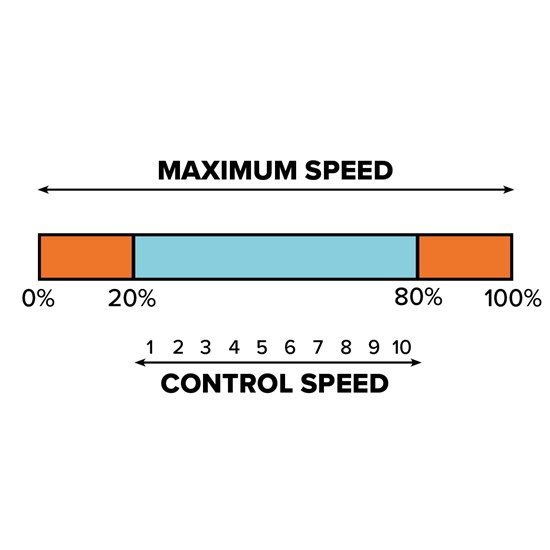

If a variable control of speed is required then you should use the 0V-10V interface terminal instead, leaving the select terminal unconnected. Once a system has been commissioned by setting the ‘min’ and ‘max’ dial positions, Ecosmart creates 10 intervals of speed between these set positions.

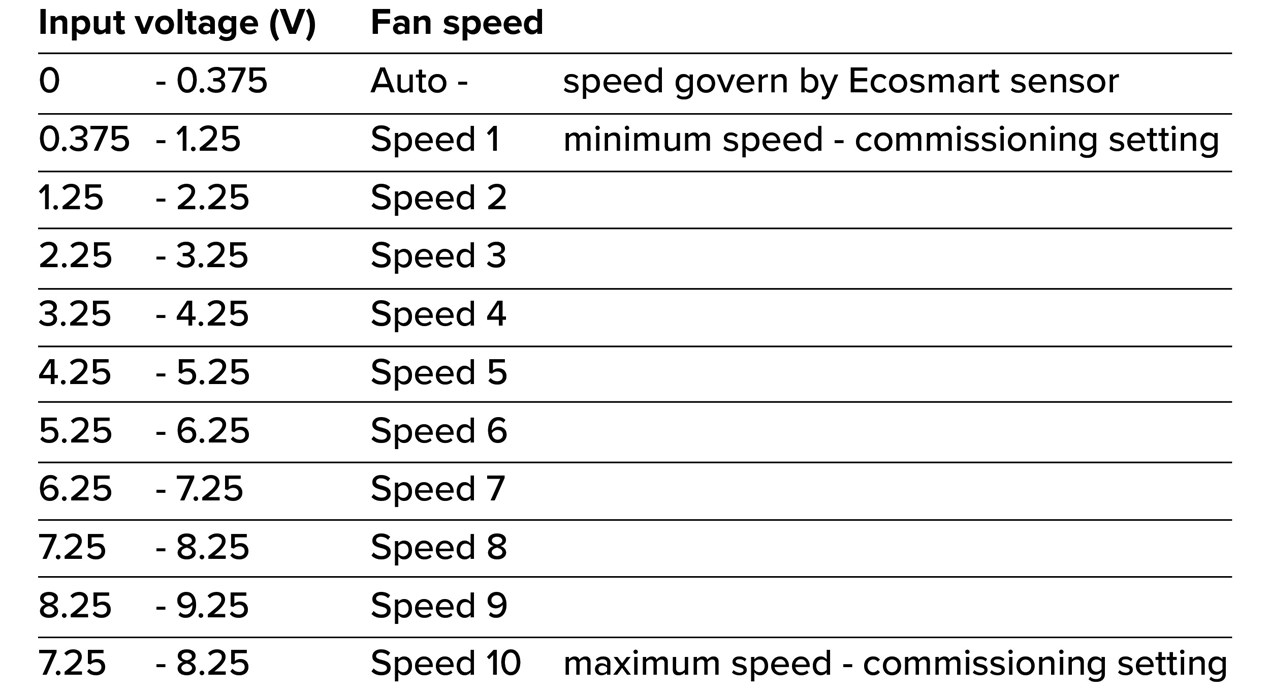

These 10 speeds can be selected by applying the required Voltage to the 0V-10V terminal of the ES-CI, the following look-up table provides the voltage ranges required to achieve each speed setting:

The first voltage band 0V-0.375V has a special property, called ‘auto’. This is a useful function of the ES-CI system, as you can instruct the fan to respond to local sensors for its speed control. For example: if there is a carbon dioxide sensor also connected to the fan then, when in the ‘auto’ position, the fan speed will be governed by the sensor.

Multiple sensors can be added for various metrics such as humidity, temperature, or carbon dioxide on a ‘highest-takes-precedence’ basis. Driving up the voltage present at the 0V-10V terminal will override the sensors and force the desired fan speed. This can allow control engineers to create powerful, yet cost-effective control strategies, combining local sensors with BMS authority at very little extra cost.

The Heat and Cool Terminals

Some Nuaire Ecosmart devices can contain heating and cooling components, such as BPS, Neptune, Ecosmart Boxer, and XBC+. The ‘heat’ and ‘cool’ terminals can be opened and closed to control these functions. The target air-off temperature for these modes of operation is set by the control thermostat on the Ecosmart control board. For example: XBC+ with an internal LPHW coil, the air-off temperature is set internally to 19°C. When the ES-CI ‘heat’ terminal is closed, the system will automatically regulate the flow of water through the coil to reach the desired temperature of 19°C, first taking account of any free heating available via the heat recovery system. If the target is being met, the valve will close and regulate the supply air temperature accordingly. Selecting cooling mode will achieve a similar effect when cooling devices such as coils are connected.

Putting it Together

By combining ES-CI with the standard Ecosmart controller, most basic BMS functions can be achieved in a simple, cost-effective way. Using sensors and local settings to automate some functions is an ideal way to control energy without the expense of a fully integrated BMS solution.

For more information on Ecosmart controls, or for help with unit and controls selection please call us on 029 2085 8200 or email info@nuaire.co.uk